The power of early specification

Before we discuss the importance of getting specified and how Building Information Modeling (BIM) can be your vehicle to success, let's start with the basics. In the world of construction, 'getting specified' is the process of being chosen and recommended for a project. It's a serious nod of approval, indicating that your product is the top choice for industry professionals.

Let's acknowledge the reality: securing product specifications for construction projects can be a great challenge. But achieving specification is not only possible but it is well within reach.

To secure product specifications as a building product manufacturer, your primary focus should be nurturing relationships with architects and specifiers rather than simply pushing product sales. It is important to position your company as a leading expert on the types of products you deliver and ensure specifiers have easy access to all the information they need during their research and product selection process.

Early specification allows manufacturers to engage with the AEC community during the initial design phase, influencing project outcomes. During this stage, Building Information Modeling (BIM) is what gets you a foot in. It's a critical time when designers look for inspiration and products for their projects. BIM and BIM objects make it easier for designers to envision the concept. They also facilitate product selection, accuracy, and shared information.

That said, the design phase is critical for manufacturers. But why? According to the Digital Built Environment Institute, 80% of manufacturers are more likely to get specified if included in the initial design phase. Your products stand out when they come with easy-to-reach, accurate data that showcases what they can do.

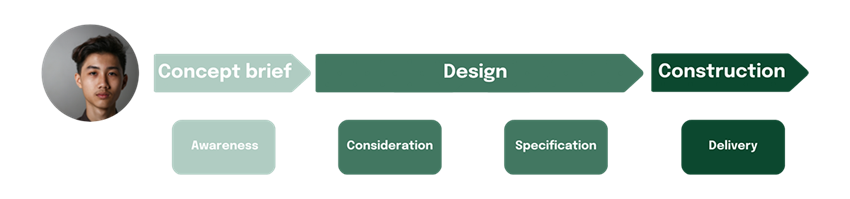

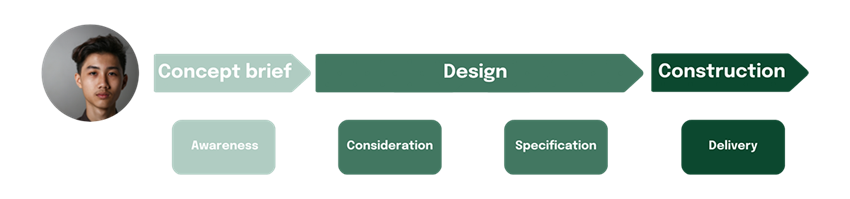

Designers aren’t mere customers exploring products for personal consumption. They are professionals who design buildings and suggest purchasing products to private and public clients. Specification begins with the client’s concept brief. Then, it’s up to the architect/engineer to create a design and consider suitable products.

Designers assess the object's geometry, performance data, and aesthetics. If it's up to par, it's downloaded into the model. The data is then collated into a common data environment. Manufacturers who create and supply BIM objects immediately have a competitive advantage. You are essentially providing a time-saving shortcut to your products, and most importantly, you’re speeding up the decision-making process and, as a result, the journey to specification.

Interested in early specification benefits? Start with us today

When building product manufacturers collaborate and offer accurate product data, they play a crucial role in minimizing future errors and simplifying the calculation of a project's environmental impact. BIM’s biggest perk is solving problems already in the planning stage before the shovel hits the ground.

Understanding the AEC community and its processes

Every player involved in a building project relies on manufacturers like you to bring their visions to life. Specifiers depend on your product data to consolidate their work.

However, the catch is that only a minority of manufacturing companies have established effective methods for engaging with architects, leading to limited success in product specification.

Did you know 68% of AEC professionals prefer to find products online? - A clear preference between physical and digital modes of product exploration. According to our 2022 survey, 42% of architecture, engineering, and construction professionals claim to spend most of their time finding compatible products, but almost 40% struggle to find manufacturers like you.

Want to make it easier for specifiers to find you? Here’s how >

Engagement, specifications, and outreach have evolved significantly over the past few years. With the widespread digital solutions in our industry, traditional ways are changing. BIM has become an essential method for contractors, architects, and engineers. Governmental bodies are also adopting BIM.

The AEC community is often pressed for time and heavily relies on digital working methods. If we consider their significance in getting products considered, it's worth looking at who they are, what they value, and where they get their information from. It's not enough to have a great design—it has to be measurable.

Learn more about why specifiers use BIM >

Maximizing the Benefits of Early Specification through BIM

Early specification with BIM empowers manufacturers to actively participate in project execution and ongoing operations, gaining insights into their product's journey. Manufacturers can collect data on potential challenges during commissioning, installation, and product operation by tracking products across projects.

Top 4 practical benefits we get through early specification

1. Simplified design process: By visualizing the entire project digitally, architects can identify issues early on, choose the right products, and save time during the design process.

2. Building long-term relationships: Providing product information on platforms like BIMobject.com builds trust and credibility, increasing the likelihood of future collaborations.

3. Accurate cost estimations: Linking product specifications with cost data enables real-time cost analysis during design, ensuring budget compliance.

4. Sustainability: By integrating sustainability data, architects can make informed decisions about materials and building systems, leading to more environmentally friendly designs.

Psst! Prodikt supports your digital products from BIM to the building. Collecting carbon data along the way.

Employing BIM is vital to ensuring project specifications. At BIMobject.com, you can reach over 5 million registered users, architects, engineers, interior designers, and construction professionals—all browsing for the perfect components for their projects.

Interested in learning more about how BIMobject can help you get your products specified? Explore our solutions today!

Denisse Luna

Content Marketer