Digitization: Taking ladders to the next level.

At first glance, ladders haven’t changed much in 10,000 years. A painting in Spain’s Spider Cave shows a person gathering honey with a ladder which doesn’t look much different from the ladders we use today. In reality, ladders are constantly evolving.

One of the people taking charge of the change is Matt Moore: a seasoned Sales Manager with more than a decade’s experience at Precision Ladders. He started at the workshop in 2011, learning how to build ladders, stairs, and hatches. Today, he manages 39 sales representatives across the US, Canada, and Puerto Rico. Matt reflects on his years and says that the ladder business has changed dramatically in just the last decade:

“We did everything on paper when I started working here 11 years ago. Now nearly everything is digital. Practically the only paper we still use is shipping labels.”

Founded in Tennessee in 1942, Precision Ladders creates aluminum ladders and stairs affixed to buildings and related equipment such as roof hatches and safety rails. The majority of their business is for industrial and commercial construction in North America, but their product solutions are offered worldwide.

Explore Precision Ladders' offering on BIMobject.com >

Explore Precision Ladders' offering on BIMobject.com >

“Nearly every architect uses BIM.”

A company won’t celebrate its 80th Anniversary if they don’t stay on top of ever-evolving customer needs. Digitalization has moved from an outlier to a standard part of our personal and professional lives in the last decade. According to our 2022 survey, 80% of architecture, engineering, and construction professionals intend to adopt more digital tools in years to come.

Precision Ladders didn’t – and don’t – stand idle to emerging digital trends. When the manufacturing company noticed that an increasing number of professionals used BIM (Building Information Modeling), the manufacturing company quickly took action to meet the demands. Matt elaborates:

“In 2013-2014, about half of the architects I spoke to said they used Revit. But things changed quickly; a year later, it was 75%. When we saw how the industry was moving, we invested in creating models of our products. Now nearly every architect uses BIM.”

BIM: Bringing in deals

How can a manufacturer work with and serve those who use BIM? The answer lies in offering manufacturer-specific BIM objects that architects can use to populate the BIM model. The manufacturing company met the initial demand by developing 52 BIM files for Revit in 2015.

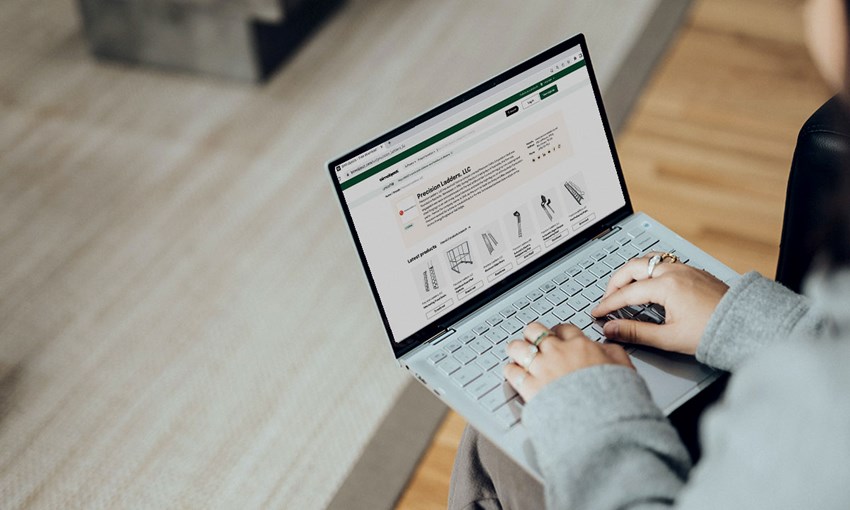

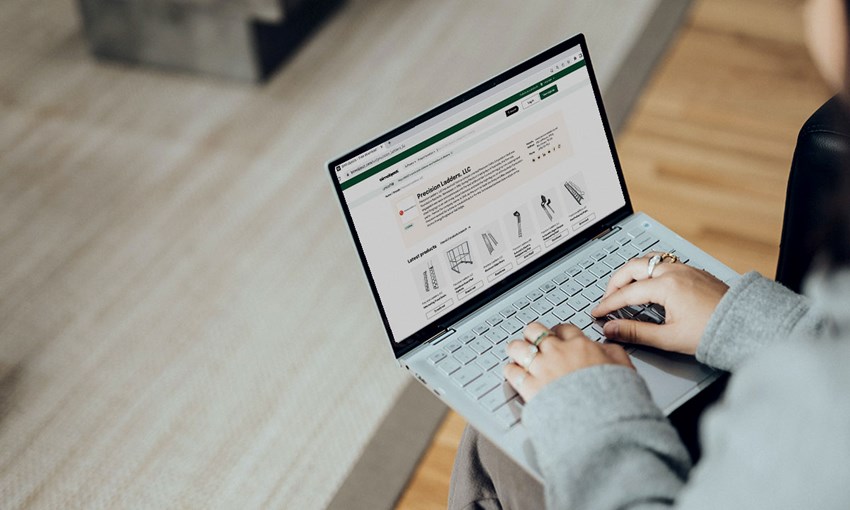

Matt Moore explains that Precision Ladders wants to be present wherever it’s easiest for architects to get ahold of their products – physical and digital. So they recreated and consolidated their BIM objects with the help of BIMobject’s content development team and published them on BIMobject.com. The positive results were immediate:

“The downloads have grown since Day One,” says Moore. “We see more quotes and orders because we offer BIM objects.”

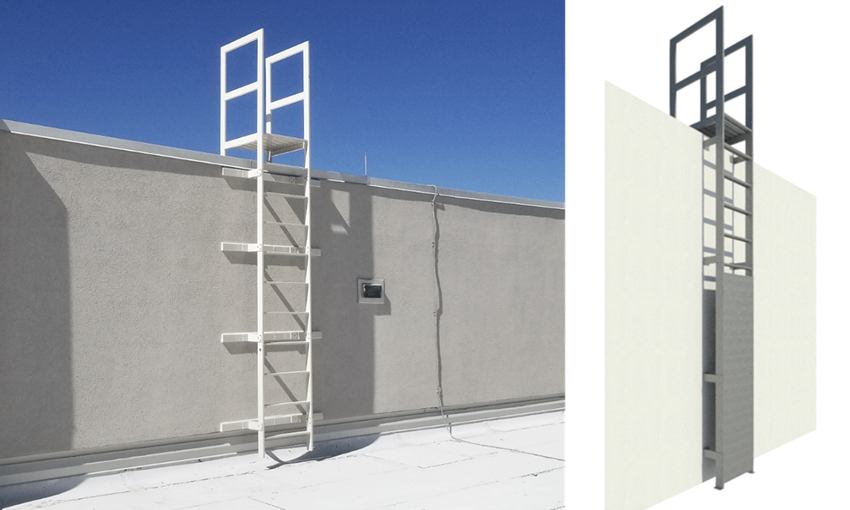

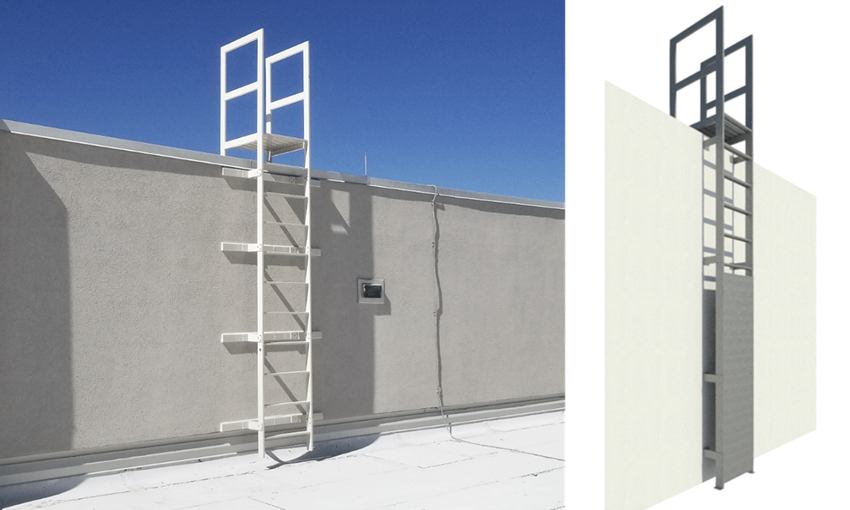

Precision Ladders' Heavy Duty Fixed Aluminum Wall Ladders depicted physically and digitally.

Safety standards built-in

The people at Precision Ladders are experts on OSHA (Occupational Safety and Health) regulations and building codes – even teaching continuing education classes on them – and making sure the BIM models reflect the correct standards for different jurisdictions and building types.

“Everyone has to follow the regulations correctly – architects, contractors, subcontractors, and manufacturers. Compliance is better and easy to verify when we digitalize the safety requirements,” Moore says.

Turning a recession into a digital opportunity

Precision Ladders has survived world wars, recessions, and inflationary eras, and then had to navigate a global pandemic. The construction industry stumbled under logistics problems, raw materials scarcity, and erratic pricing.

“We wanted to be ready for when the recovery began, so during the pandemic, we invested in digital tools,” Moore says. “We updated our website and invested in our Revit models. We wanted to have a firm foundation and offer better materials for the architects when the economy improved.”

Putting BIM files at the front and center

Precision Ladders placed their BIM files at the center of their online presence. Quite literally. Their BIM object offering has the place of honor as the top center tab on their website menu. Moore explains that they want their information to be readily available to architects. When architects have a need, he wants to be ready and knows this has resulted in new clients and sales.

Some architects thought 52 models were too many to choose from. Precision Ladders listened to their feedback and worked with BIMobject’s BIM content experts to consolidate their offering to 11 objects.

“In essence, we focused on more quality content and better information management,” says Moore. “BIMobject gave us great advice, conducting research for us and hitting every deadline. They gave us fair, quality advice in a timely manner.”

Investing in BIM objects is a win-win

Their investment in digital tools like BIM has paid off, and Precision Ladders is entering its 80th year in excellent health. Matt ends the interview with a piece of advice for building product manufacturers:

“If you want your products included in projects, you need to have digital models available. Make it easy for the architects, because time is money,” Moore says. “It’s great when we get feedback from an architect who found us on BIMobject and says ‘This was exactly what we needed. Thank you!’”

Sarah Chase

Global Content Marketer